Madeblades

Madeblades

Madeblades

Madeblades

To reduce the levelized cost of energy (LCOE) of offshore wind energy the MADEBLADES project aims for a 30% reduction in cost of large (>90m) offshore wind turbine blades. By developing new paradigm-shifting concepts for design, material usage and manufacturing processes the new disruptive blade design will improve the competitiveness.

This will be done by implementing new automated lay-up process where fiber preforms are precisely placed in the blade mould by robots. This will give a huge advantage compared to current manufacturing techniques because they are based on inefficient, manual processes due to the size and complexity of the wind turbine blades. This automation is therefore expected to reduce the moulding time, person-hours and material cost which all reduces the cost and improves the competitiveness of the wind turbine blades.

Predictive simulation of wrinkle creation in fiber preforms

Automatic placement of fiber-binder preforms in the blade mould may introduce wrinkle defects if it is not handled correctly. Wrinkles are known to cause severe knockdown on the strength of wind turbine blades. The aim of this project is to predict the creation of wrinkles in fiber-binder preforms during forming and investigate the effect of process parameters on wrinkle characteristics and severity. During this project several interesting technical aspects needs to be addressed. Among other things, the model should be capable of describing the very specific behavior of dry fiber reinforcement, and the binder interface in-between plies needs to be characterized and modelled, to accurately describe the wrinkle mechanisms.

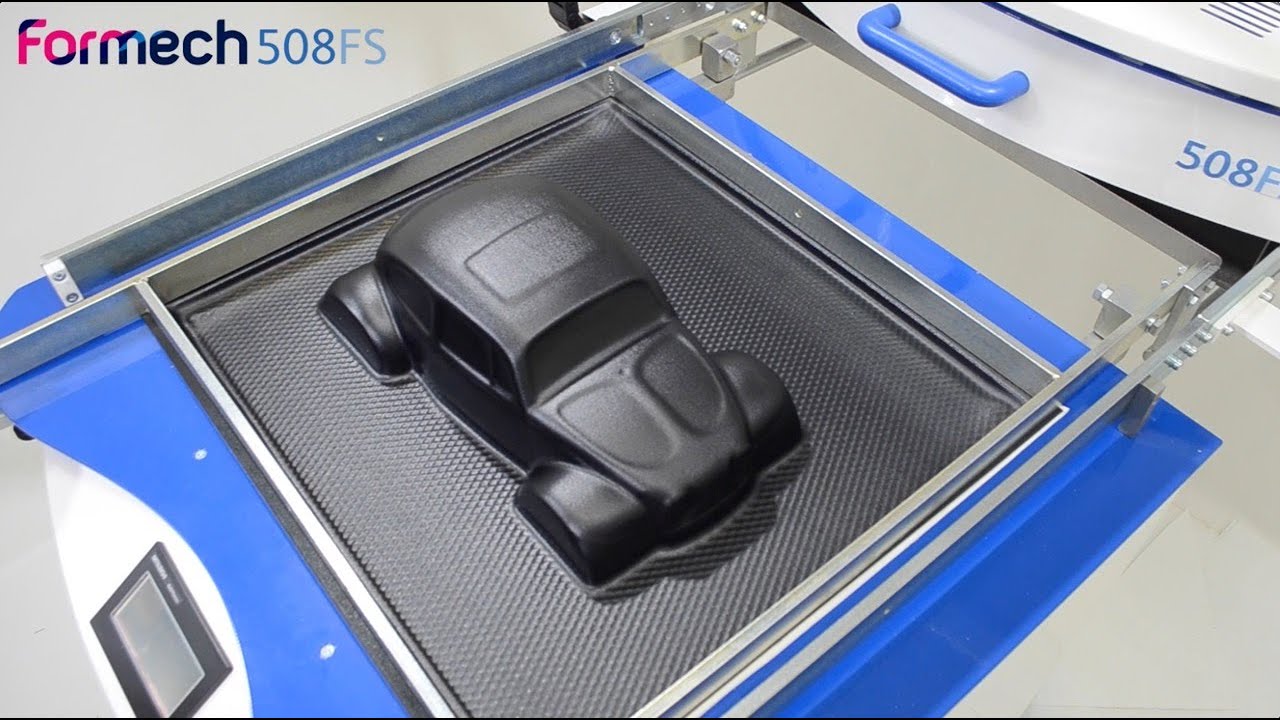

Vacuum forming of fiber preforms

Structural design criteria for interfaces between preforms

To reduce mould cycle-times of large-scale laminated composite structures, the concept of preforms is being investigated. Preform in this case refers to a stack of unwetted fiber material, which is built outside of the casting mould, and then moved and placed as a single coherent unit. When multiple preforms are used an interface is created between them which may provoke unexpected failures if not designed correctly. This interface is therefore being characterized and structural design criteria are being developed to allow the use of preforms in the design of large composite structures.

More information